Corrosion Engineering Services

Registered Service Disabled

Veteran

Owned Small Business Located In Alvin, Texas.

We are a highly skilled and knowledgeable Corrosion Engineering Services company bringing elite level, value-added capabilities to the Government.

Contracted Engineering Services for Corrosion Problem Resolution.

FOR INNOVATIVE COMMERCIAL SOLUTIONS Safe and sustainable use by various Unit Process and Unit Operations such as surface coating, cleaning, stripping, and plating.

WE KNOW WHAT THE CORROSION MECHANISMS ARE.

We eliminate them. we know how to implement the corrosion public law and DOD regulatory demand

THREE THINGS

01

Process improvement through Innovation. Eliminate blast rework. Improve process efficiency.

02

PMO Introduce our innovations from industry. Collaborate with each other.

03

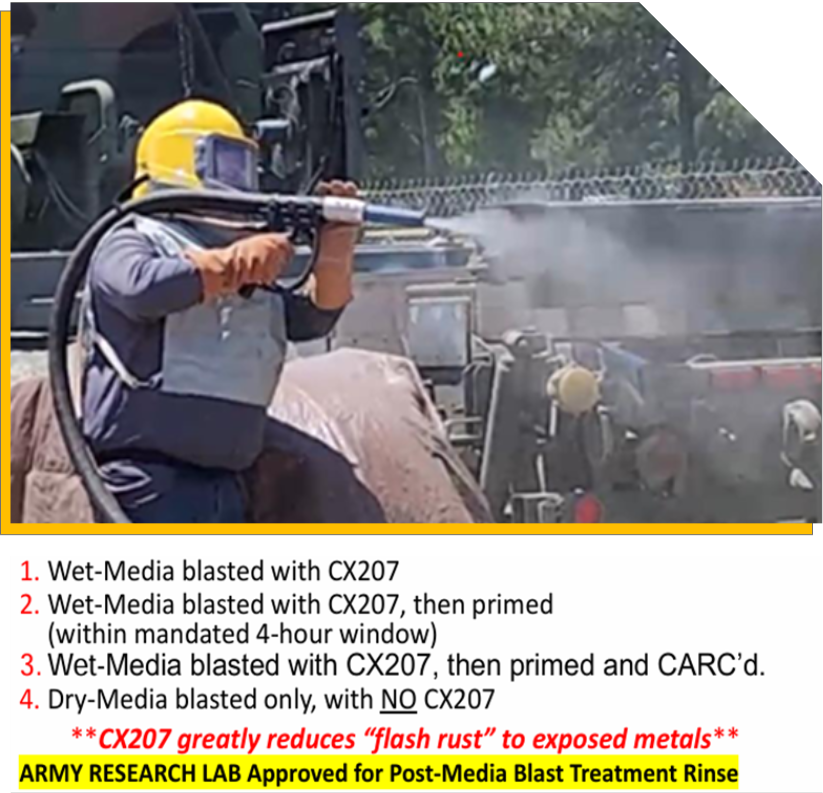

Test and Evaluation. Seeing is believing. With or without ARL.

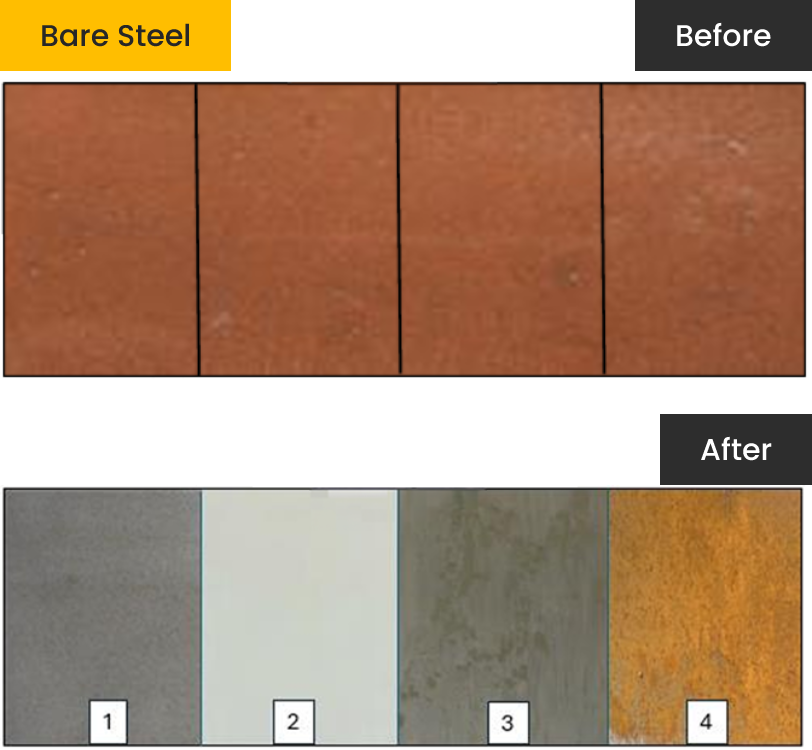

TESTED AT RRAD ON VEHICLE “MILITARY-GRADE” STEEL

Conducted controlled experiment on 11 June 2024 at RRAD on Vehicle “Military-Grade” Steel (MIL-A-46177) • Used a bare steel plate exposed to the elements for over 5 years. • Abrasive is fused Magnesium Ortho Silicate mixed with CleanWirx207 as a Passivating- Agent at the molecular level. Sample exposed outside to the elements as of 11 October 2024 (4 full months).

TESTED AT RRAD ON VEHICLE “MILITARY-GRADE” STEEL

Conducted controlled experiment on 11 June 2024 at RRAD on Vehicle “Military-Grade” Steel (MIL-A-46177) • Used a bare steel plate exposed to the elements for over 5 years. • Abrasive is fused Magnesium Ortho Silicate mixed with CleanWirx207 as a Passivating- Agent at the molecular level. Sample exposed outside to the elements as of 11 October 2024 (4 full months)

WE BRING EXPERTISE, EXPERIENCE, AND EXCELLENCE

– Extensive track record of working with military installations to test and prove product effectiveness.

– Team includes Certified Corrosion Inspectors authorized by AMPP under federal law.

Senior executives bring:

– Technical teaching/training skills.

– Background in Department of Defense and commercial vehicle industry.

Ex-military maintenance personnel (Officers and NCO's) with expertise in:

– Maintenance protocols and operations.

– Corrosion correction and mitigation.

Additional expertise in:

– Focus on corrosion-related aspects.

– Previous work with companies like Oshkosh Truck, General Motors, Caterpillar, and Electro-Motive Diesels (locomotives).

Who We Are: